|

|

|

|

|

|

#1 |

|

Still Watching My Back

|

And this is what you get

I then biscuited the bottom on  And put a little bit of weight on top  I then went to work on the top.  I wanted to put in glass so I made sure it had a lip to hold the glass in.  I mitered and biscuited the edges and then glued and assembled   I then wanted to route the sides. Since I didnít own a router table I made one. Here is out if turned out.  So I routed the corners.  I then took my Spanish cedar and cut to fit and lined the sides of the box.

|

|

|

|

|

|

#2 |

|

Still Watching My Back

|

And the back

I then biscuited the top onto the box  It was then time for the door. I wanted to make a raised panel door where the raised panel was Zebra wood. Expensive but only slightly more expensive than plan glass and cheaper than bevelled glass. I cut the pieces to size  And routed them to fit together. Using only a little it of glue on the rails. The stiles were not glued so that they may expand with the humidity. I later sealed this with silicone as it will allow the wood to move  I then made the base. I had left over zebra wood that I put in like a keystone. Everything is held together with biscuits. One of my best purchases was the biscuit joiner.  Freehand routing  LOTS of sawdust, I set off my fire alarm about 10 times making this cabinet. And I covered my workshop/ storage room in sawdust. Move everything out that you donít want covered in sawdust before starting a project of this scale  I then biscuited this to the base  And by this time the box was enough weight to hold it all in place  And the base Spanish cedar (friction fit, no glue)

|

|

|

|

|

|

#3 |

|

Still Watching My Back

|

I then installed the door. Note that the cedar had to be chiselled out so that the full overlay door would sit flush over the opening

It was then all sanded and I started to apply the finish. Linseed oil was first     I had to stick to a strict schedule because I didnít have much time. Only 2 weeks. So between my 6 coats of varnish that I put on after the stain I worked on the inside drawers and shelf. We have wood.  And make Drawers. Note the difference in the patternÖ Thatís how you know that it is handmade

|

|

|

|

|

|

#4 |

|

Still Watching My Back

|

And then once the 6 coats of varnish were on (sanding in between each second coat) I installed the drawers

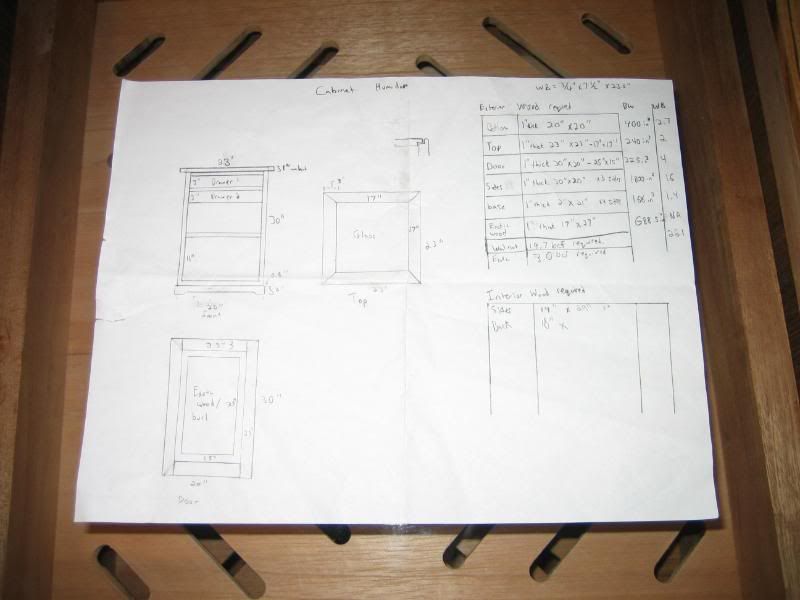

I made a simple shelf and then installed the glass with one inch thick Spanish cedar and covered the whole rim in weatherstripping for a good seal.      Not too bad for 2 weeks start to finish. I didn’t have time to sand this down as I took these pictures 4 hours before I had to be out the door for a flight back to school. One last pic is the initial master plan  When I get back in May I am putting in dividers and humi beads. Needless to say I spent my cigar budget already! I Hope you like it as much as I do.

Last edited by O-Danger; 01-06-2009 at 09:06 PM. |

|

|

|

|

|

#7 |

|

Patriot

|

holy **** man, that looks great. very nice handy work.

__________________

Author of  eath, Disease, and Life at War: The Civil War Letters of Surgeon James D. Benton, 111th and 98th New York Infantry Regiments, 1862-1865. eath, Disease, and Life at War: The Civil War Letters of Surgeon James D. Benton, 111th and 98th New York Infantry Regiments, 1862-1865.

|

|

|

|